RoHS stands for Restriction of Hazardous Substances that has been in usage since 2006. Also known by the name, directive 2002/95/EC, it is now mandatory and necessary for all manufacturing companies to abide by this regulation as it keeps the environment and human health safeguarded and under constant check from certain hazardous or lethal substances used in various products.

These products are:

- Lead (Pb)

- Cadmium (Cd)

- Mercury (Hg)

- Hexavalent chromium (crvi)

- Polybrominated biphenyls (PBB)

- Polybrominated diphenyl ethers (PBDE)

- Bis(2-ethylhexyl) phthalate (DEHP)

- Butyl benzyl phthalate (BBP)

- Dibutyl phthalate (DBP)

- Diisobutyl phthalate (DIBP)

Why is RoHS compliance testing important?

RoHS testing is done in specialized laboratories where the concerned authorities and lab professionals test the quality and composition of a particular product. The usage of the above-mentioned substances can be detrimental to the environment and hence the products need to be tested before being launched in the market.

Products having these substances are listed as pollution and harmful landfills that can pose death risks to workers and humans. Mostly, this compliance framework applies to companies in the European Union.

The RoHS compliance testing is applicable for the following products:

- Electronic devices like ICs, PCBs, soldering equipment, CPUs, wires, circuit boards, and many more

- Household utensils

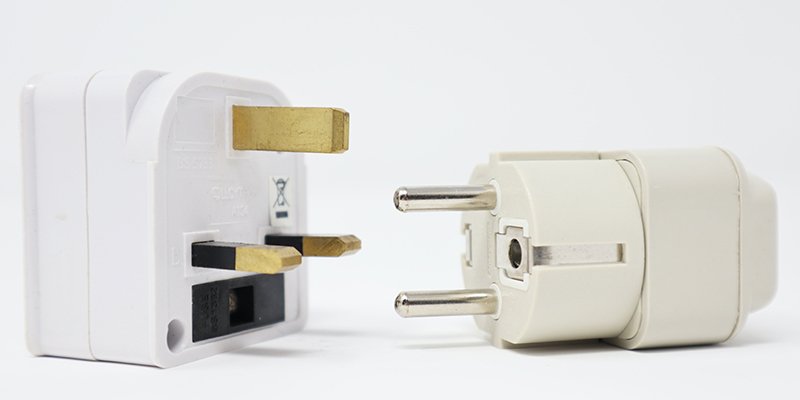

- Power adaptors

- Power tools

- Electronic toys

- Lighting products like tubes, bulbs, LEDs, and much more

Apart from the listed items, certain medical instruments, and monitoring devices are also tested under the RoHS directive framework.

How is this testing done?

As mentioned before, RoHS compliance testing is done in specialized labs where a thorough chemical testing of the product is conducted.

They test the feasibility, reliability, and accuracy of the products based on certain chemical criteria. Moreover, the ratio of restricted or banned items is also measured through wet chemical testing, and advanced spectroscopy and chromatography. All these scientific methods allow the lab professionals to determine the exact levels of the restricted substances used in the tested products.

Though, all the substances mentioned in the above list can be used in a product, manufacturers have to use them at set levels, which is under 0.1% of the total weight of the product by the compliance framework of RoHS.

You can trust the process of Enviropass chemistry testing laboratory, which uses the best techniques to test various products.