A vacuum is a tool utilised in many industrial manufacturing processes, bottling, including packaging, drying, degassing, and pick and place, to mention a few. In these procedures, an industrial vacuum pump is utilised to create, improve, and maintain the vacuum. There are many numerous types of industrial vacuum technology, which will be discussed in this article. You can get ample information on LeDab vacuum pumps on the website.

- Rotary Vane Pump with Oil Seal

The gas enters the inlet port of the rotary vane pump and is caught by an eccentrically positioned rotor, which compresses the gas and sends it to the exhaust valve. When atmospheric pressure is exceeded, the spring-loaded valve opens, allowing the gas to escape. The vanes are sealed and cooled with oil.

The number of stages utilised and their tolerances determine the pressure achieved with a rotary pump. A two-stage configuration with a force of 110-3 mbar is possible.

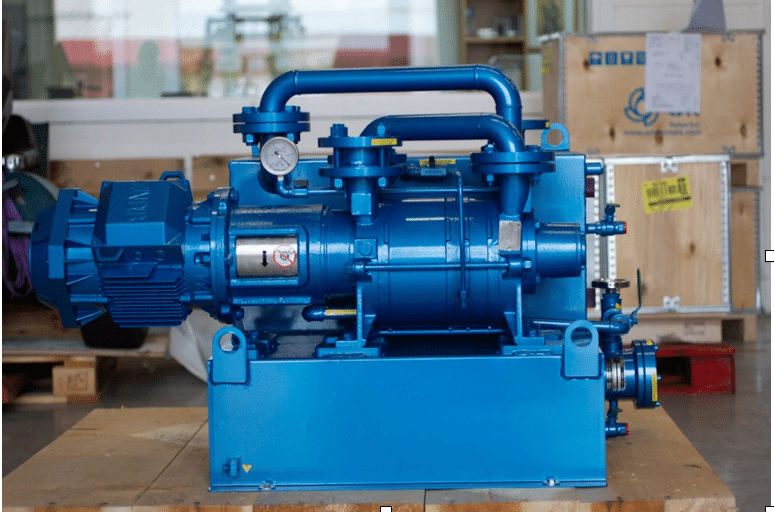

- Pump for Liquid Rings (Wet, Positive Displacement)

A vaned impeller positioned eccentrically within the pump housing compresses the gas in the liquid ring pump. The liquids are pumped into the pump, where it creates a moving cylindrical ring against the interior of the casing due to centrifugal acceleration. This liquid ring forms compression chambers by developing seals in the gap between the impeller vanes.

The cyclic change in the volume encompassed by the vanes and the ring, which compresses the gas and releases it through a port at the end of the housing, is caused by the eccentricity between the impeller’s axis of rotation and the pump housing. The shaft and impeller are the only moving parts in this pump, making it simple and reliable.

- Pump with Diaphragm (Dry, Positive Displacement)

A rod riding on a cam rotated by a motor rapidly flexes a diaphragm, causing gas to flow into one valve and out the other. It’s tiny and easy to maintain. The diaphragms and valves have an average lifetime of over 10,000 operational hours. In clean, high vacuum applications, the diaphragm pump is employed to support compact compound turbo-molecular pumps.

It’s a sample preparation pump with a small capacity that’s extensively used in R&D labs.

Lastly,

Although the several types of vacuum pumps have been briefly explained here, a more in-depth examination of each is required to comprehend the benefits and drawbacks of each technology properly. You can choose anyone from the above list that would cater to your needs.